In the rapidly advancing high-tech industries, particularly in the fields of new energy, advanced materials, and high-end manufacturing, the demand for purity and stability in production environments has reached unprecedented levels. The inert atmosphere glove box, as an indispensable precision experimental and production equipment in these sectors, provides robust support for scientific research and manufacturing with its unique design philosophy and exceptional performance.

Overview of Product Features

An inert atmosphere glove box, as the name suggests, is a sealed workspace filled with high-purity inert gases and equipped with systems to continuously filter out reactive substances. Its core advantages lie in the efficient removal of O₂, H₂O, and organic gases, making it ideal for applications requiring ultra-pure, anhydrous, oxygen-free, and dust-free environments. These include lithium-ion battery and material production, semiconductors, supercapacitors, specialty lighting, laser welding, and 3D printing. The glove box serves as an essential apparatus for scientific experiments in universities, research institutions, and corporate laboratories, and is widely adopted in industries such as biochemistry, metallurgy, electronics, chemical engineering, geology, mining, and pharmaceuticals.

The entire lifecycle of the product—from design, procurement, production, and finance to sales, after-sales service, and enterprise management—is governed by comprehensive information and systematic management systems. This ensures precise monitoring and traceability at every stage of manufacturing, significantly enhancing production efficiency, product quality, and the reliability of delivery timelines.

Production Equipment

The manufacturing of inert atmosphere glove boxes utilizes globally renowned high-precision machinery from brands such as OKUMA, DMG, MAKINO, Mazak, HAAS, and TRUMPF. These advanced production systems not only guarantee product quality but also enable continuous capacity expansion to meet growing market demands.

Notably, inert atmosphere glove boxes are available in a wide range of configurations and support extensive customization. Users can integrate multifunctional modules tailored to specific needs, including solvent purification systems, evaporation coating systems, vacuum heating systems, temperature control units, industrial refrigerators, automated transfer systems, and electron microscopes. Specialized modules such as nitrogen removal systems, hydrofluoric acid scrubbers, and CO₂ elimination units are also designed for the lithium battery industry, addressing unique requirements across diverse fields.

Functional Principles and Structural Composition

The core functionality of the inert atmosphere glove box lies in its gas purification and circulation system. Under the precise monitoring of dew point and oxygen analyzers, the inert gas within the chamber undergoes continuous purification via a closed-loop system comprising pipelines, purification columns, and circulation fans. As the gas circulates through the purification columns (water and oxygen adsorbers), moisture and oxygen are efficiently removed, returning purified gas to the chamber. Over time, this process reduces water and oxygen levels to <1 ppm, creating an ultra-pure and stable environment for experiments or production.

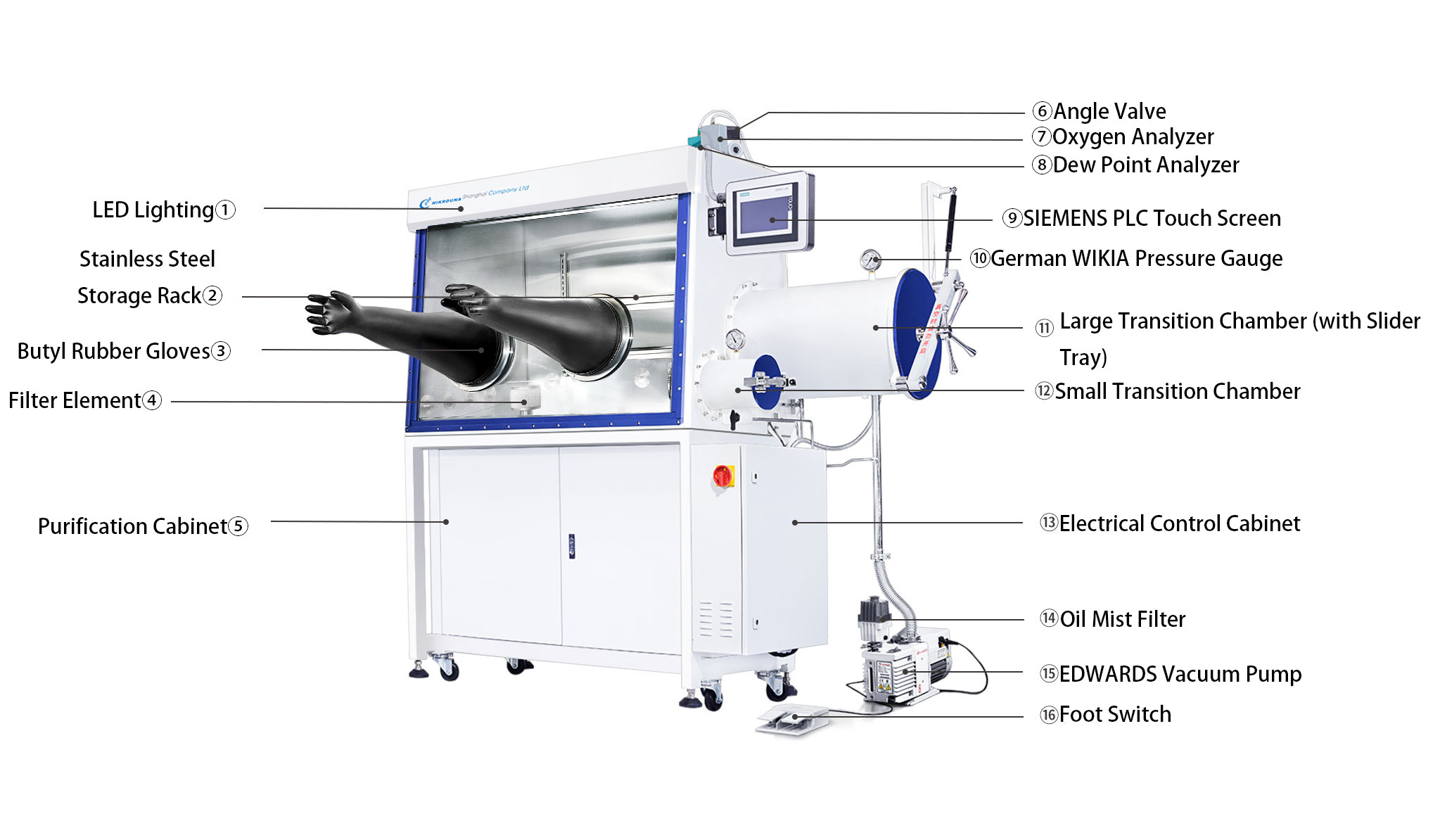

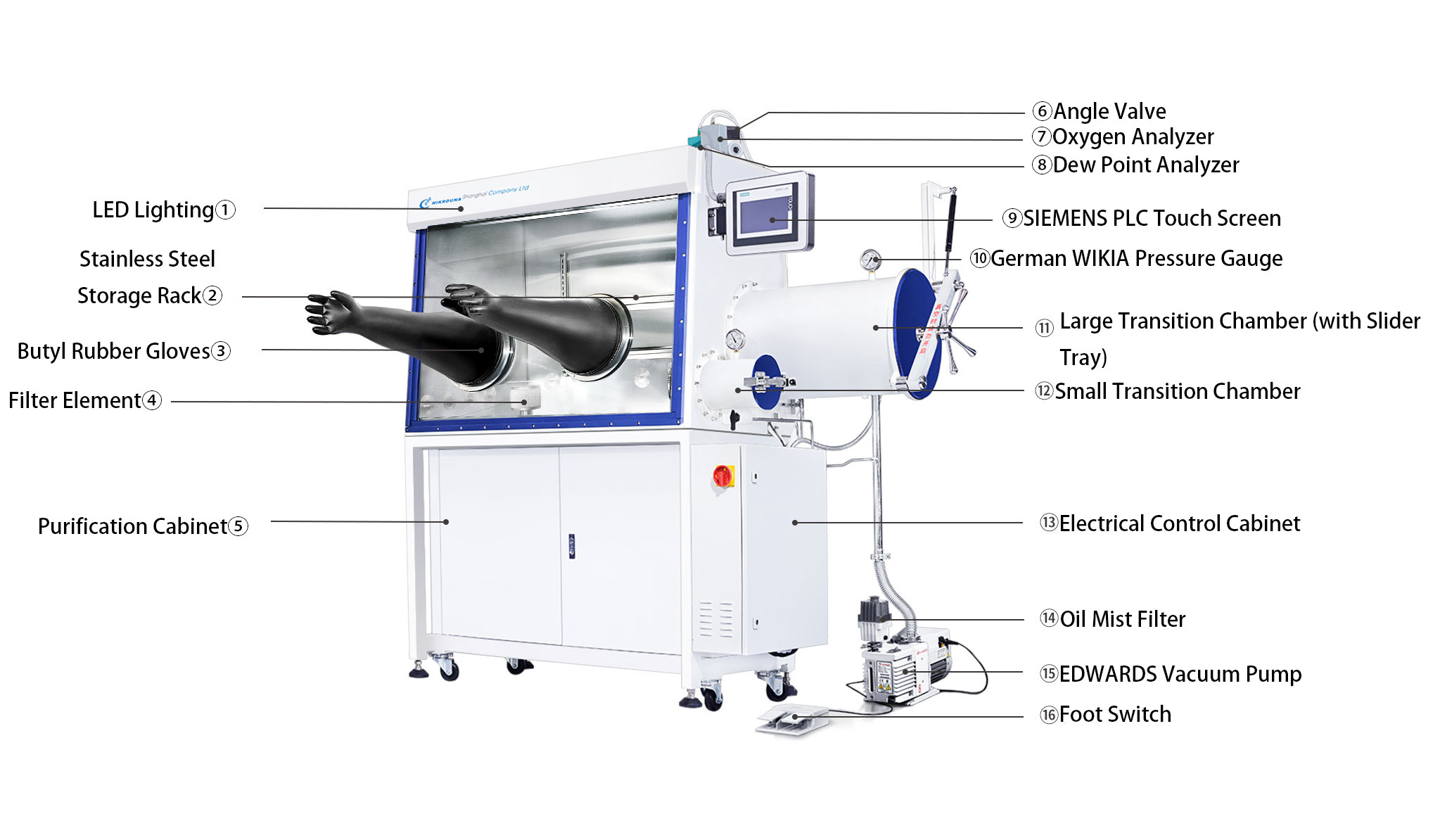

Structurally, the glove box consists of:

- A 304 stainless steel chamber (thickness ≥3 mm) with customizable interior surfaces (oil-brushed, chemically mirrored, Teflon-coated, or acid-passivated) and exterior finishes (electrostatic spray or acid passivation), ensuring durability, aesthetic appeal, and ease of cleaning.

- Components such as viewing windows, glove ports,gloves, filters, shelves, lighting, KF flange interfaces, purification systems, circulation fans, organic solvent adsorbers, dew point analyzers, oxygen analyzers, pressure sensors, transition chambers, vacuum pumps, and electrical control systems.

- High-elasticity, corrosion-resistant gloves for ergonomic operation and long-term reliability.

- The purification system employs regenerable/reducible materials (e.g., copper catalysts and molecular sieves) controlled by an automated program to efficiently eliminate O₂, H₂O, and organic gases. The circulation system integrates high-performance fans with adjustable airflow to ensure rapid gas turnover and effective purification.

Broad Applications

Inert atmosphere glove boxes play an irreplaceable role across multiple industries. In lithium battery R&D and manufacturing, they provide ultra-clean environments for material preparation and testing, enhancing battery performance and safety. They are indispensable in physicochemical research, powder metallurgy, nuclear technology, OLED/PLED development, pharmaceuticals, material processing, solar cells, 3D printing, specialty lighting, fine chemicals, and polymer materials.

A standout feature is the integration of advanced P₂O₅-based dew point analyzers and ZrO₂-based oxygen analyzers. The dew point analyzer resists corrosion in environments involving lithium batteries and organic solvents, enabling regeneration and reuse—a solution to the single-use limitation of traditional sensors. The oxygen analyzer extends fuel cell lifespan by preventing direct exposure to air.

Conclusion

With its integrated information management systems, cutting-edge production capabilities, diverse configurations, customizable solutions, innovative functional design, and broad applicability, the inert atmosphere glove box stands as a cornerstone of modern scientific research and industrial production. As technology advances and markets expand, its unique value and versatility will continue to shine across even more domains.